The new high-end product range of MW cables for lab, systems and platform usage. Based on the ultimate technology of MW cables.

The cables are qualified to extreme environmental conditions, and tested to the MIL-Standards below.

The Neoflex family consist of cables up to 12GHz High power 1Kw, 18GHz low loss 0.72 dB/m, and low loss up to 40GHz with 2.5dB/m.

Cable sizes from 3 mm diameter up to 12.2 mm diameter provide a wide range of cables -

The Neoflex cables have a variety of ruggedizedion options and are engineered using the basic cable design and construction to enhance the handling characteristics of the finished assemblies.

Captivated contact terminations provide long-term interface stability.

These assemblies were designed from the ground up to provide reliable microwave connections you can count on.

| Neoflex 160 | The smallest 4 mm cable sized for optimum loss of 2.5dB @ 40 GHz. |

| Neoflex 162STR | High flexibility 4 mm cable with stranded center conductor 1.5dB @ 18 GHz. |

| Neoflex 142 | Optimized 5 mm cable 1.1 dB @18 GHz, the best tradeoff between loss and size. |

| Neoflex 142STR | High flexibility 5 mm cable with stranded center conductor 1.35dB @ 18 GHz. |

| Neoflex 142STR-105 | High flexibility 5.4 mm cable with strandard center conductor. |

| Neoflex 235 | Optimized 6 mm cable 1 dB @18 GHz, the best tradeoff between loss and size. |

| Neoflex 270STR | High flexibility 7 mm cable with stranded center conductor 1dB @ 18 GHz. |

| Neoflex 335i | Optimized 8 mm cable 0.72 dB @ 18 GHz, the best tradeoff between loss and size. |

| Neoflex 450STR | Optimized for low loss 0.42 dB @ 12 GHz performance with great power handling. |

| Neoflex 480 | Lowest Loss 0.36 dB @ 10 GHz uses a stranded center conductor to enhance the handling. |

Advantage of the Neoflex MW cable family

Wide temperature range

-55 to +200 °C for most cable types

-55 to +200 °C for most connector types

Mechanical protection

A wide range of armors are available for most Neoflex cable types.

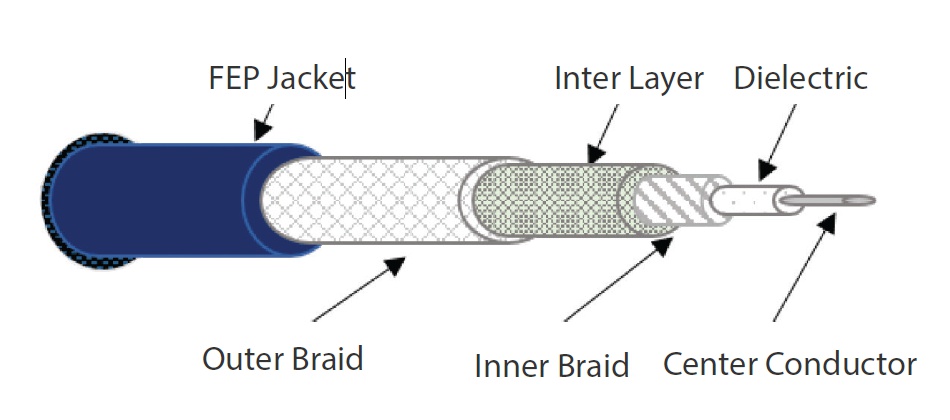

Chemical stability Thanks to excellent materials (FEP).

Lowest losses and excellent stability vs. Temperature

0.2 dB/m @ 18 GHz for Neoflex

Lowest Phase over temperature

650 ppm over -55 to +75 deg. C

High power performance

Neoflex LLEF335i withstanding

400 Watt CW @ 18 GHz

Low weight, small diameter

Neoflex family of cables use expanded PTFE tape which reduces the weight of any given cable by 20-35 % as compared to other technologies while still maintaining same electrical performance.

Likewise smaller diameter cables are achieved for same electrical performance vs. thicker cables using other technologies.

Wide frequency range

Neoflex Family from DC up to 40 GHz.

All connectors are made according to the following materials and MIL standards:

| Body of connector | Stainless steel. Corrosion-resistant, non Magnetic 303, Per ASTMA484 and A582. |

| Center conductor | Beryllium Copper per ASTM-B-196, QQ-C-530. |

| Insulator | PTFE per ASTM-D-1 710 |

| Finish | Center Conductors and solder components Are plated p e r MIL-G- 45204 Type I I , Class 1 Over nickel plate per QQ-N-290. Body and Body components shall be Passivated per ASTM A380. |

| Interface | All Connectors Interface per MIL-STD 348 and MIL-PRF- 39012 accordingly. |

| Environmental | All Connectors meet MIL-STD-202- per the Following tests: |

| Temp. Range | -54 to +155 deg C. |

| Thermal shock | MIL –STD 202 Meth.107 Cond B |

| Vibration | MIL –STD 202 Meth. 204 Cond B. |

| Shock | MIL–STD 202 Meth. 213 Cond I. |

| Waterproofing | IP67 and on selected types IP68 |

| Material option | SS-316 per request. |